PakVitold

May 20, 1935, Stalino, USSR (now Donetsk, Ukraine) —

December 25, 2002, Donetsk, Ukraine

Mining fan “Pivnich” (“North”)

Humans began extracting minerals from the earth at least forty-one thousand years ago. The Ngwenya Mine, located in the southeast of the African continent, is considered the oldest in the world. The first mineral mined was hematite, iron ore. However, in the Stone Age, it obviously was not used for smelting of iron, but for painting. Some of the paintings that archaeologists found on the walls of rocks and caves were made of ocher, a paint that even today is made of hematite.

Of course, the first mines had a fairly simple design and relatively small depth, but in the Middle Ages, its depth reached more than a hundred meters, they became multilevel with numerous galleries and had forced ventilation systems because at this depth air could quickly turn into a deadly mixture of gases.

First of all, it happens because people inhale oxygen and exhale carbon dioxide. Breathing in a deep mine without ventilation is almost the same as breathing in a hermetically sealed room. That is a pretty bad idea.

Secondly, coal extracted from the Earth’s crust begins to oxidize in the mine. Carbon (C) binds to oxygen (O₂), which is part of the air, and... hello, carbon dioxide (CO₂)!

If the air on the Earth’s surface contains 21 % oxygen, and the level of carbon dioxide is very low (only 0.03 %) then almost all the oxygen can be converted to carbon dioxide in the mines. Miners call this air “dead”. One breath is enough for everything to be ended in a tragedy.

In addition, there is methane, an explosive gas without color and odor, which is contained in coal seams and escapes into the air of the adit from there. As far as it is lighter than air, it gathers under the “ceiling” of the adit. The concentration of methane from 9 to 14 % is the most dangerous. Before the advent of gas analyzers, which today measure gas concentration and signal when to leave the mine, miners used canaries for these purposes. Being more sensitive than humans to changes in air composition, birds sang incessantly if the amount of methane was within normal limits. As its level was increasing, the canaries fell silent and the miners hurried back to the surface. There were also so-called “burners” in the mines, which went down to the mines after the end of the work shift. They crawled through the adits, holding long torches in their hands, and simply hoped that the concentration of methane above their heads was not so high and that they could simply burn it. From time to time methane exploded. Even today, methane explosions are the cause of most accidents, which, although not so often, still occur in mines.

If you look at the number of minerals extracted ever, it turns out that in the twentieth century, 90 % of all coal, 87 % of iron ore, 80 % of copper ore, and 70 % of gold were extracted from the ground. It explains why nowadays the search for new deposits began even in the most remote corners of the Earth.

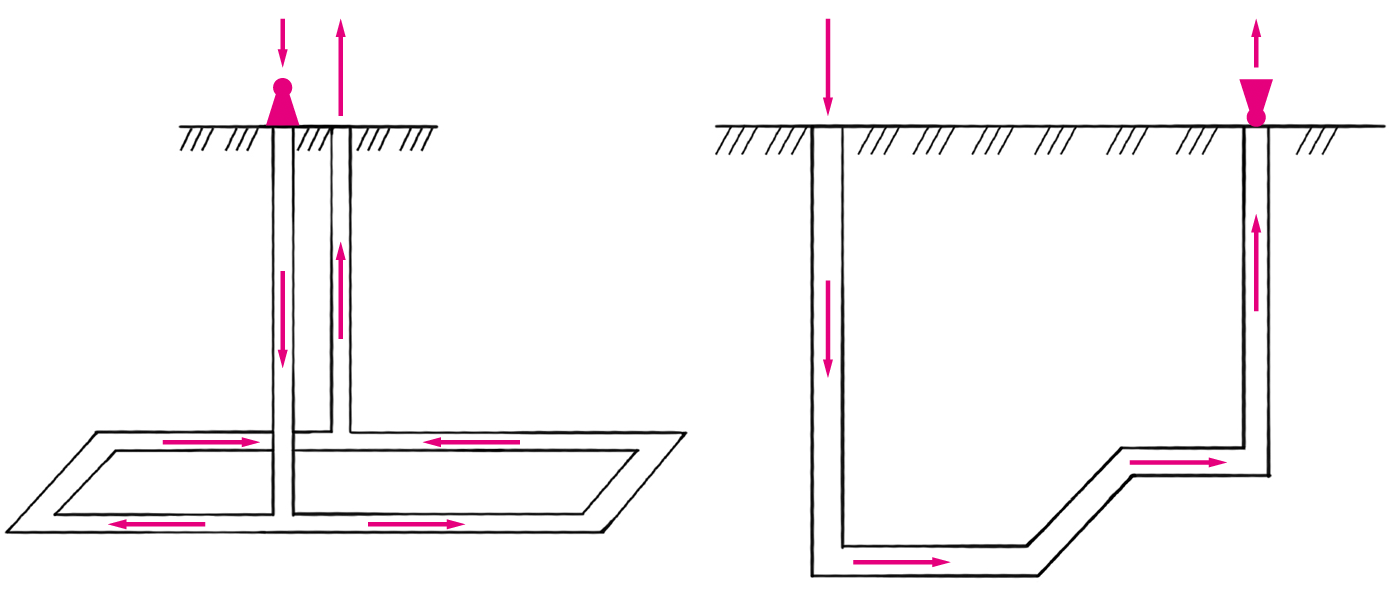

Ventilation scheme by injection method (left) and suction method (right)

For example, during the expeditions of

Even today the modified models of the fan continue to be manufactured and used for ventilation of mines and quarries that are deep or difficult to ventilate.

The main ventilation fans are responsible for supplying air to the entire mine and are installed on the ground near the wellhead of the hermetically sealed shafts. They work continuously.