LyulkaArkhip

March 23, 1908, Savarka village, Russian Empire (now Kyiv Oblast, Ukraine) —

June 1, 1984, Moscow USSR (now Russia)

Twin-circuit turbojet engine

In 1968, the American military transport aircraft Lockheed

In 1941 the Ukrainian engineer Arkhip Lyulka revolutionized aircraft construction by patenting the design and principle of operation of a double-circuit turbojet engine. The idea was almost thirty years ahead of its time, back then in the 1940s, there were no lightweight and heat-resistant composite materials to turn drawings into a working model.

There is nothing complicated in jet propulsion. This is how the balloon moves, if you inflate it, forget to tie it and let it go, so the air comes out in one direction and the ball flies in the opposite direction. Everything is simple... So far we are not discussing how to force the plane to work in this way.

When Lyulka graduated from Kyiv Polytechnic Institute in 1931 and moved to Kharkiv, aircraft were still equipped with piston engines like automobiles, but there was still hope for constructing an efficient steam engine. The engineer mentioned that when it came to the idea of designing a turbojet engine, “many people simply did not understand how a jet entering ‘something’ and coming out of ‘something’ could move an airplane”. Fortunately, the cutting-edge and largest turbogenerator plant in Europe was opened in Kharkiv, and Lyulka gained the opportunity to conduct his experiments there. By the way, Frank Whittle in Great Britain and Hans Joachim Pabst von Ohain in Germany conducted similar studies.

In fact, Whittle patented the world’s first working gas turbine (turbojet) engine back in 1930, and Ohain registered a patent for his jet engine in 1935.

The world’s first turbojet-powered aircraft Heinkel He 178 equipped with HeS 3 engine designed by Ohain made the first flight in 1939. Then, in 1941 the first British jet-engined aircraft Gloster

It may seem Lyulka lost the competition because he patented his invention only in 1941, but it is not.

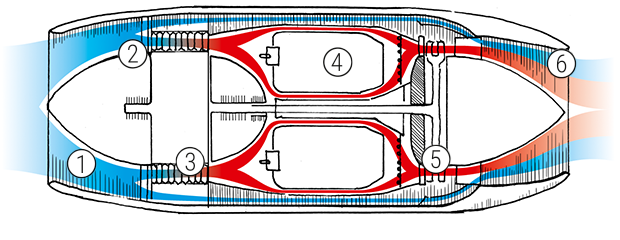

Twin-circuit turbojet engine

1. Input diffuser

2. Fan

3. Compressor

4. Combustion chamber

5. Gas turbine

6. Rocket engine nozzle

The application which he submitted, said that this engine differed from already available models in that it had the low-pressure fan and distribution of air stream on two, one of which passed on an internal contour, and the second on an external one.

While Whittle and Ohain were working on a turbojet engine where the air passed through one internal circuit, Lyulka was working on a twin-circuit engine. He quickly realized that the engines of both the Whittle’s and the Ohain’s construction would consume too much fuel, which would be a problem if it is needed to cover distances of more than 2,500 km or achieve traction enough to lift a large number of passengers on board what meant that so low-cost would not be so cheap, although Lyulka hardly thought about the latter.

It is said that the next revolution in the aircraft industry is just around the corner: nowadays several startups are testing fully electric motors. But so far, manufacturers for the most part just continue to improve the engine, designed by a Ukrainian engineer 80 years ago from year to year.

In single-circuit engines, all the air that enters is mixed with the fuel in the combustion chamber, then the hot gases fly out of the nozzle and create a jet thrust.

In twin-circuit engines, one part of the air enters the combustion chamber, and the other bypasses it and due to the design of the engine under high pressure, and immediately enters the nozzle. Therefore, in twin-circuit engines, thrust is created by both air mixed with fuel and ordinary compressed air.