BenardosMykola

July 8, 1842, Benardosivka, Kherson Governorate, Russian Empire (now Mostove, Mykolaiv Oblast, Ukraine) —

September 21, 1905, Fastiv, Russian Empire (now Ukraine)

Electric arc welding

Five or six thousand years ago, humans learned to make one piece out of two pieces of metal. They folded them together, heated them to red or even white, took a stone ax hammer, and struck pieces so hard and so many times that they joined at the interatomic level. Blacksmiths of that time performed this work. However, if the metal was soft enough, for instance, gold, copper, or meteoric iron, it was not necessary to preheat it. This metal could be joined by anyone who had enough strength and something heavy at hand.

How reliable was this method of welding? In the 5th century AD, Indian blacksmiths welded an iron pillar weighing about six and a half tons and more than seven meters high. It still stands in Delhi and even did not get rusty.

However, the story continues. Forge welding technology was improved, some processes were automated. In the middle of the 19th century, blacksmiths welded metals on an industrial scale. Many products were welded, and some of them were huge as ship anchors weighing more than five tons.

In 1873, the Ukrainian inventor Mykola Benardos decided to build an all-terrain steamshipthat could maneuver in shallow waters and bypass obstacles on land, if they occur on the river. Some parts for the steamship had to be welded from metal, but there was no place for large blacksmith furnaces in Benardos’ workshop, so he decided to use an electric arc to heat the metal.

In the early nineteenth century, an Italian Alessandro Volta just designed the first chemical source of electricity, and then physicists found that if you connect two carbon rods (positive and negative ones) to this source of electricity and combine them to close the circuit, and then pull them a short distance apart, an electric arcthat looks like a strip of light or lightning will appear between them. The current will continue to move in a circle, but now its movement resembles jumping in the air from one end of the rod to the other. If rods are moved too far apart from each other, the electrical circuit will break and the glow will disappear.

Benardos thought that if you took a piece of metal instead of one rod and attach another piece of metal to its edge, the directed electric arc would help heat them enough that the blacksmiths could weld them.

During the work, Benardos noticed that if you heat the edges of the metal a little longer, you could wait until they began to melt, and when they cool and dry, a monolithic and strong joint would form, even without hammer blows. This is not surprising, the temperature inside the electric arc usually reaches

The idea of an all-terrain steamship failed, but Benardos invented a new and surprisingly simple way of joining and separating metals and called it «Electrogefest» in honor of the ancient Roman god of fire.

In 1881 he went to Paris because his method of welding became the main exhibit at the International Electrotechnical Exhibition and even won a gold medal.

Due to lack of funds, Benardos was unable to apply for a patent immediately after the exhibition, so he received a patent for “Method of separating and joining metals by using electric current” for ten years only in 1886. However, the patent was applicable only in the Russian Empire.

Then Benardos found an investor, Polish engineer, and businessman Stanisław Olszewski. Together, they have received patents in France, Belgium, Great Britain, Austria-Hungary, Sweden, Italy, Germany, the United States, Norway, Denmark, Spain, and Switzerland. Together they opened the enterprise “Electrogefest” in St. Petersburg, which specialized in welding. By that time, Benardos had improved the welding process enough that it could be implemented to produce the most complex parts and structures. However, constant experiments had other consequences. Working on the improvement of the lead batteries design, the inventor got severe poisoning, which later reasserted itself.

But at that time the work was in full swing: specialists from all over Europe were constantly training in the open workshops of “Electrogefest”, and Benardos often went to one or another plant to set up the process. In a few years, electric arc welding has become the standard for joining metal parts in more than a hundred factories in Western Europe and then around the world.

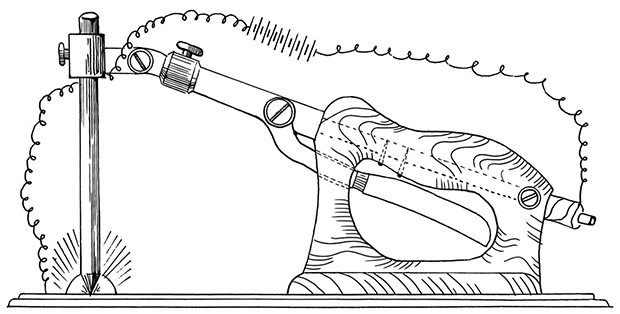

Drawings of the device from the patent of Benardos