BakhmutskyiOleksiy

March 17, 1893, Petro-Maryivka village (according to other sources, Sokologorivka village), Russian Empire (now Pervomaisk, Ukraine) —

September 25, 1939, Pervomaisk (now Luhansk Oblast, Ukraine)

Coal combine

“The world still needs coal”, say the World Coal Association and the statistics.

Today, coal provides 38.2 % of electricity generation. Although every year power stations that use renewable sources like solar energy, wind, water, and thermal motion of atoms, molecules, and other particles increase in number, coal will be covering 22 % of world energy demand by 2040.

In the nineteenth century, miners extracted coal in much the same way as it happens now in Minecraft, they went down the mines and chopped off lumps from bigger chunks of coal with a tubber, a tool similar to a pickaxe. After that, they had to load the coal into wagons, roll it back on rails to a lifting cage (cabin) to finally lift it to the surface. These wagons weighing

Under these conditions, one miner could extract two tons of coal in twelve hours. By the way, nowadays one underground shift lasts no more than six hours.

With the onset of the Industrial Revolution in the 1780s, the demand for coal skyrocketed, and engineers started to think about how to automate processes and increase the productivity of miners. The whole process was divided into several main stages:

Cutting is the process when underground layers of coal are cut. It is similar to what we are doing when cutting a cake to take one piece of it.

Fragmentation — the process of separation of a part of the coal layer and its simultaneous breakage. We don’t usually do this with a piece of cake, but imagine that we decided not to carefully put it on a plate, but to grind it to crumbs beforehand.

Loading — the process of the loading of fragmented coal on the conveyor belt to transport it to the surface. The only thing we can do with what was once a piece of cake is to put it on a plate.

Engineers began to seek solutions for each of these stages. The jackhammer was introduced in 1897, the electric mine locomotives were invented at the beginning of the XX century, around that time the first mining machines appeared: loaders, as well as cutting machines for cutting rocks. But it still did not ensure the required speed.

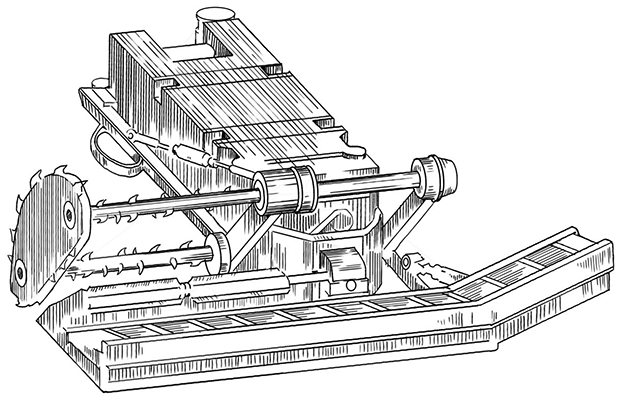

And so in 1931 in the Soviet Union competition was announced for the designing a mining combine, a machine that would perform all these operations simultaneously. Oleksiy Bakhmutsky took part in the competition. At that time he worked as the chief mechanic of the Pervomaisk Mining Administration in Donbass, and before that from the age of thirteen, at the “Tatiana” mine in the village of Petro-Maryivka.

The participants of the competition offered combines of fifty different designs. The design by Bakhmutskyi was the best. In 1932, the workers of the Pervomaisk Mining Administration created the world’s first combine, which could simultaneously cut, fragment, and load the coal in the face.

And on August 17 of the same year, the

Like many other inventors, Bakhmutskyi learned engineering not in school, but by practicing. He started with observing the operation of underground pumps, then worked at an electromechanical workshop, and a military factory during the First World War. When he returned to the mine, he coordinated the launch of coal cutters purchased abroad. At first, it was one machine, then five more, then he began to improve the conveyors, which required frequent repairs. That is how he learned the working principles of all mechanisms and connected them into one machine.

Since 2010, the coal mines worldwide produce from seven to eight billion tons of coal each year. Modern combines produce from five to fifteen thousand tons of coal per day, i. e. they work

Shakhtarska-Hlyboka is the deepest coal mine in the world, with a depth of over 1,500 meters. The mine was opened in 1986 in Shakhtarsk in the Donetsk Oblast.

The